Why Regenerated Transformer Oil Is Necessary for Reliable Power Systems

The vital function of regenerated transformer oil in making sure the dependability of power systems can not be overemphasized. By recovering the oil's fundamental chemical and physical properties, the regeneration process significantly improves its dielectric toughness and thermal performance. This not only curtails the chance of insulation failings however also adds to the longevity and performance of transformers. As we discover the multifaceted advantages of this technique, the ramifications for both operational prices and environmental sustainability become significantly obvious, elevating essential concerns about just how these factors interaction in contemporary electrical facilities.

Value of Transformer Oil

Transformer oil plays a crucial function in the effective operation of electric transformers. By providing thermal conductivity, transformer oil dissipates heat created during electric procedure, which is important for keeping optimum operating temperature levels and lengthening the life-span of the equipment.

Furthermore, transformer oil functions as an obstacle versus moisture and air, which can result in oxidation and destruction of transformer materials. The existence of contaminants in the oil can dramatically impair its shielding properties, causing functional inefficiencies and prospective devices failure. Routine surveillance and maintenance of transformer oil are therefore critical to ensuring the continued performance of transformers.

The high quality and make-up of transformer oil are critical, as they directly influence the integrity and performance of the electric systems in which they operate. Recognizing the importance of transformer oil is vital for utilities and sectors reliant on durable power infrastructure, emphasizing the need for reliable monitoring and regeneration procedures to keep oil honesty in time.

Advantages of Regeneration Process

In addition, the regrowth process mitigates the degradation of oil, which can result in increased oxidation and acid formation. This not only enhances the dependability of the oil but likewise reduces the danger of transformer failings as a result of insulation break down. The boosted high quality of regenerated oil permits transformers to run at optimal levels, eventually causing boosted power effectiveness and reduced functional expenses.

Furthermore, the regeneration process contributes to maintaining the general health of the power system. Transformers can run longer without the demand for oil substitute, thus decreasing downtime and upkeep efforts. In recap, the regrowth process provides substantial benefits by boosting the durability and efficiency of transformer oil, ensuring that power systems operate reliably and successfully with time.

Environmental Influence and Sustainability

The regeneration procedure of transformer oil significantly relieves environmental worries connected with oil disposal and waste management. Traditional disposal methods for made use of transformer oil posture significant threats, including Check Out Your URL soil contamination and water contamination. By regenerating oil, these threats are substantially decreased, as the process reuses existing resources rather than adding to lose accumulation.

Additionally, regenerated transformer oil can be recycled in different applications, which advertises a circular economy. This not just lessens the need for virgin oil removal-- a procedure that can be eco harmful-- but likewise conserves natural deposits. The regeneration procedure itself utilizes advanced purification and filtration strategies that eliminate unsafe impurities, guaranteeing that the end product surpasses or meets market standards for efficiency and safety.

Enhancing Transformer Performance

Considerable improvements in transformer performance can be achieved with using regenerated transformer oil. This oil, created with sophisticated filtration procedures, dramatically improves the electric insulation residential properties of transformers. By getting rid of impurities and pollutants that typically endanger efficiency, regenerated oil makes certain premium dielectric stamina, reducing the threat of electrical failings.

Furthermore, regenerated transformer oil displays boosted thermal conductivity, which assists in efficient heat dissipation. This particular is crucial for maintaining optimum operating temperature levels, thus lengthening the life-span of transformers and minimizing the possibility of overheating - Reclaimed Transformer Oil. Boosted thermal management additionally adds to the total reliability of power systems

Additionally, the chemical security of regenerated oil avoids the formation of destructive acids and sludge, which can dig this adversely impact transformer components. By preserving a cleaner interior environment, this oil reduces upkeep requirements and prolongs service intervals.

Cost-Effectiveness and Efficiency

In regards to cost-effectiveness and performance, restored transformer oil offers a compelling alternative to standard oils. The regeneration procedure not just removes pollutants but also recovers the oil's original residential properties, extending its practical life-span. This durability translates into lowered regularity of oil substitute, therefore lowering operational expenses over time.

Furthermore, making use of regrowed oil can substantially diminish energy losses connected with ineffective insulating liquids. Its superior dielectric residential properties guarantee ideal efficiency, boosting the dependability of power systems. Because of this, services take advantage of lower upkeep prices and lowered downtime, cultivating an extra effective functional setting.

Verdict

Finally, the regrowth of transformer oil plays an essential role in ensuring the dependability and effectiveness of power systems. By bring back the crucial chemical and physical buildings of the oil, this procedure enhances dielectric stamina and thermal conductivity, ultimately lowering the risk of insulation malfunction. The ecological advantages associated with recycling sources contribute to sustainability initiatives, while cost-effectiveness and improved performance highlight the necessity of utilizing regenerated transformer oil in modern electric infrastructure.

Transformer oil plays a crucial duty in the reliable operation of electrical transformers. Normal surveillance and maintenance of transformer oil are consequently essential to guaranteeing the proceeded effectiveness of transformers.

The regrowth procedure of transformer oil dramatically eases ecological worries connected with oil disposal and waste management. By lengthening the lifecycle of transformer oil, the energy and resources normally eaten in generating new oil are significantly reduced.Substantial improvements in transformer efficiency can be accomplished via the use of regenerated transformer oil.

Tia Carrere Then & Now!

Tia Carrere Then & Now! Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Christy Canyon Then & Now!

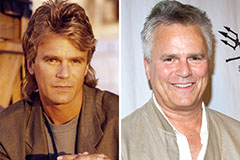

Christy Canyon Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!